How one Austin machinist is pushing back on America’s job-shop habit, one project at a time

America’s precision machinists are searching for balance. On one hand, the business of contract manufacturing has become a lowest-cost, shortest lead-time proposition (read how, in space procurement).

On the other hand, when provided room to operate, companies are leaning-in to engineering, to design-to-manufacture, to an operating ethos that values quality and acumen and technology and everything that goes into being globally competitive. All things that differentiate American suppliers.

Fortunately, more companies are getting a chance to manufacture a product and not just job-shop a part. Domestic production is in favor, and a new generation of manufacturers is busy reinventing US industry, in a flurry of eye-catching products.

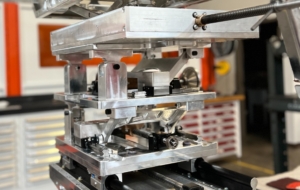

Daniel Hester, founder and CEO of Austin-based American Precision Engineering (APE), leads one of those companies. Hester maneuvered APE into an opportunity to design-and-build the aptly named “Universal Lift System” for one of America’s top VTOL aircraft manufacturers — and the project provided his company an opportunity to do what it does best.

“It was a wheelhouse project for us,” Hester says. “There were a lot of engineering challenges — and we have a lot of experience with lifting attachments and developing lifting equipment and material handling. Engineering and designing a solution and then being able to build it for them is what we do best.

“But we’re also this scrappy and nimble company, and it enabled the customer to cut out the middleman and work directory with us — and that’s no small thing,” Hester says. “Our customer is building VTOL aircraft — they have significant design and manufacturing challenges in their products; they didn’t need an additional challenge to design a lift system and figure out how to build it as well. And that’s where our value came in.”

The lift system, which the Austin Regional Manufacturing Association (ARMA) recognized as the Coolest Product Made in Austin, plays a role both in aircraft assembly — like affixing wings — and with lifting key components like batteries into the fuselage.

“So, the premise with the universal lifting system,” Hester describes, “is a core platform that then has a modular set of tooling that can be used for a variety of manufacturing uses. It’s a mobile platform with a vertical actuator; it opens up a lot of uses, especially in aviation.”

APE’s prototype was a hit. The company is already working on building several production units.

But as great as the ULS turned out, the subtle way that Hester’s team turned a procurement request into a demonstration of capabilities is an equally compelling outcome. “In the end, it was solving a very complex geometry problem — how can we figure out how to get all this functionality into a very small space from what essentially began as a crayon drawing? To be trusted with that process means everything,” he says,

“Consider the alternative. What we often see is that a customer will design something, give it to us and basically say, ‘how much to make this?’ The cost is often astronomical — and we tell them why. They go back to the drawing board, and they bring something back again. But it’s the same price for a different reason,” he laughs.

“They quite often end up throwing that part ‘over the fence’ (to offshore providers) to shop on price, when the better approach would be to hire a design-to-manufacturer like us. We’re involved from the outset, but then share in the rewards of the value we’re created,” Hester explains. “And when I talk to companies that are like, ‘oh, we send this stuff overseas,’ I’m just like, ‘how do you sleep at night? You’re literally slitting your own throat.’”

This self-defeating behavior, where companies wish there were more capable domestic manufacturing options, only to perpetuate offshore supply chains, is maddening — but also a habit that’s hard to break.

“We have Protolabs and Xometry and Paperless Parts and other companies that are aggregating quotes from so-called ‘independent companies’”, Hester says, “but what it’s doing is putting this massive amount of market pressure on price and not so much on quality. If you’re making something in your garage, that’s great. But I don’t know if it’s good long-term for a business like ours.”

Moreover, “We need, as a country, to build companies and infrastructure to be able to manufacture high-end domestic products at a globally affordable price,” Hester adds.

I’ll finish the thought: an important step is to reimagine procurement, not just production, in a way that enhances rather than diminishes the attributes of America’s new generation of capable machinists. Quality not price, prowess not profits, where community matters.

Hester’s team at American Precision Engineering, and a hundred others like them, offer a path forward.

Bart Taylor is a Moss Adams BDE and founder and former publisher of CompanyWeek manufacturing media. Reach him at bart.taylor@mossadams.com.